+86-137-8347-1727

+86-137-8347-1727

liste des produits

Produits chauds

concasseur à percussion ouverture d'alimentation: 820x700-1600x2080mm taille d'alimentation: ≤500mm application: toutes sortes de concassage de minerai, chemins de fer, autoroutes, énergie, ciment, produits chimiques, construction et d'autres industries. matériaux traitable3

concasseur à mâchoires PE ouverture d'alimentation: 150 x 250-300 x 1300 mm taille d'alimentation: 125-250 mm production:1-2200 t / h application: l'industrie métallurgique, l'industrie minière, l'industrie chimique, l'industrie du ciment, l'industrie de la construction, l'in3

concasseur à cône diamètre du cône:600-2200mm taille d'alimentation:35-300mm production:12-1000t / h application: la métallurgie, les matériaux de construction, la construction de routes, l'industrie chimique et l'industrie du silicate. matériaux traitables: le calcai3

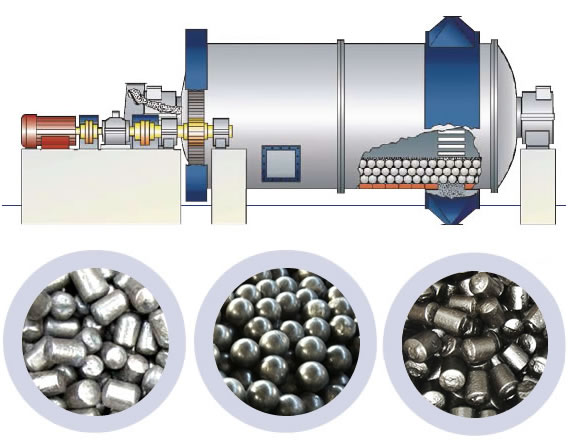

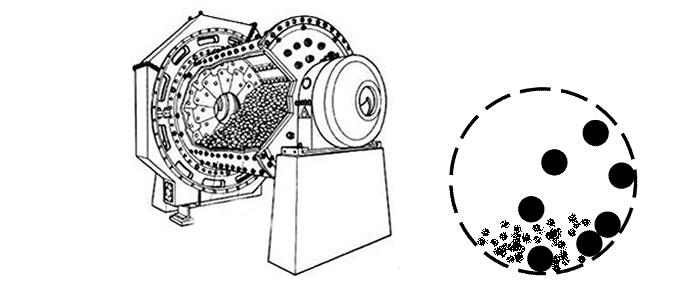

Ball mill steel ball proportioning principle

The ball mill is the key equipment for the material to be ground after crushed .The key to grind material in the ball mill is the different specifications steel balls . today we introduce the ball mill steel ball proportioning principle.

1. Determine the total ball load according to the ball mill main motor powder allowed load.

The steel balls filling rate are generally 25% - 35%, the lower steel ball load rate, power consumption is also reduced, but the productivity is also low. Therefore, the first prerequisite for verifying the total amount of steel balls added is that the sum of the weight of the steel ball and the weight of the material in the mill is less than or close to the allowable value of the motor power of the ball mill.

2. Determine the bigger steel ball diameter.

3. Measure Steel Ball Ratio reasonableness by Using Steel Ball Specific Surface Area

The specific surface area of the steel ball in the first warehouse should be 9.5-10.5 m2 per ton of steel ball; for closed ball milling with roller press, the value can be adjusted to 12-14 m2/t steel ball, and the liner is continuous lifting type, The specific surface area of the steel ball loaded in the second warehouse should be 35-38m2/t steel ball, and the steel ball with the roller press can be 38-40m2/t. The ratio between the various ball diameters should still be calculated as per larger accumulation density .

4.The principle of loading the ball that meets the main functions of the steel balls in each warehouse, combined with the type of liner used.

The materials particles fed in the first warehouse can be up to 30mm, its main function is to break. Therefore, the diameter of the loaded steel ball should be between 50-90mm in the first warehouse, and the material entering the second chamber of the ball mill is less than 2- 3mm, so its role is fine grinding, the range of the steel ball should be 15-50mm, because the fine grinding is mainly inter-grinding, using a single size ball (20-25mm), with the single corrugated lining can reach higher efficiency . If still select a certain range diameter steel ball in the second bin, can adopt grading liner, so that the bigger size ball is close to the partition plate, and the smaller ball is located at the discharge end.

5.Calculate the unit steel ball output to verify the rationality of the ball.

Accurately master the matching principle of the ball mill steel ball, can improve the grinding efficiency better,and further improve the production efficiency.

Précédent:

Machine For Cleaning SandProchaine:

Zhengzhou Hengxing 3200*4500 ball mill ready for delivery +86-371-67858720

+86-371-67858720 +86-371-67858720

+86-371-67858720 postmaster@zzhxmachine.com

postmaster@zzhxmachine.com sarapang6

sarapang6 +86-137-8347-1727

+86-137-8347-1727